Gas leaks are a constant threat to factories!

Safe field maintenance

Professional excellence team

Our experienced team of engineers can help you calibrate your gas detection equipment and keep it running smoothly, so your workers can be kept safe wherever they go.

Safe field maintenance

Gas detection management

Gas detection can make the difference between safety and tragedy. From installation support and calibration assistance to equipment repair and troubleshooting, Sanpu Instruments can provide the best solutions.

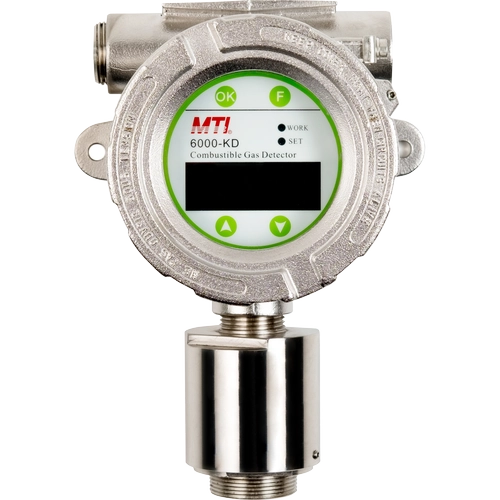

Generally speaking, gas detectors need to be calibrated and tested regularly to ensure the accuracy and reliability of the detector. For commonly used combustible gas detectors and toxic gas detectors, it is recommended to calibrate and test every three to six months, and perform self-test before each use. If the detector displays abnormality or appears abnormal during use, it should be inspected and corrected immediately.

To choose the right gas detector, you need to consider the following:

◎Types : Different gas detectors are specially used to detect different types of gases. The corresponding gas detector should be selected according to the type of gas that needs to be detected in the usage scenario.

◎Concentration : Different gas detectors can detect gas concentrations in different ranges. The appropriate gas detector should be selected according to the gas concentration requirements in the usage scenario.

◎Usage environment : The usage environment of the gas detector is also a factor that needs to be considered when choosing a suitable detector. For example, the presence of explosive gases, temperature, humidity, pressure and other factors may affect the performance of the detector. A suitable gas detector should be selected based on the actual use environment.

In addition, factors such as detector sensitivity, accuracy, reliability and maintenance costs also need to be considered. Generally speaking, to choose a suitable gas detector, you need to understand factors such as the gas type, concentration, and environment that need to be detected in the use scenario, and select a suitable gas detector based on relevant requirements and conditions. When choosing, please feel free to consult CSI Sanpu Instruments for relevant technical advice.

In the workplace, explosion protection measures may be required if hazardous substances such as flammable gases, vapors, liquids or dusts are present. Therefore, the following points may help determine whether explosion protection measures are required:

◎Confirm whether flammable gases or dusts are present in the workplace: Detecting the presence of flammable gases or dusts in the air in the workplace can determine whether explosion prevention measures are required.

◎Confirm whether there are equipment or tools with explosion-proof requirements in the workplace: For example, in coal mining, oil and gas and other industries, explosion-proof mobile phones, explosion-proof lighting and other explosion-proof equipment and tools need to be used to prevent possible explosion hazards.

◎Confirm the grade of the workplace: Based on the grade of the workplace, it can be determined whether the use of explosion-proof equipment and tools is required. For example, according to the standards of different countries and regions, workplaces are usually divided into different levels, and corresponding explosion-proof equipment and tools are used according to the different requirements of the levels.

◎Consult professional institutions or personnel: If you are not sure whether explosion-proof measures are required, you can consult relevant professional institutions or personnel, such as safety production supervision and management agencies, explosion-proof equipment suppliers, etc., to obtain more accurate advice and guidance.

In general, determining whether explosion protection measures are required in the workplace requires assessment and judgment based on the actual situation. If hazardous substances such as flammable gases, vapors, liquids or dusts are present, it is recommended to take corresponding explosion-proof measures to ensure the safety of the workplace.